| SF-2X Marginal Lubricating Bush |

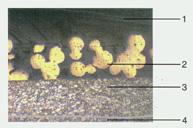

Metallographies Structure |

|

|

1.POM with lead 0.3~0.5mm

2.Porous bronze 0.2~0.3mm

3.Steel backing 0.4~2.2mm

4.Copper plating 0.008mm |

| Introduction |

| SF-2X boundary lubrication bushing is based on a composite material with 3 firmly bonded layers:steel as backing.sintered bronze sphericalpowder as interlayer and modified POM as lining layer,it fits well for low speed,heavy duty and normal temperature and saves cost and prolongs working life when replacing normal all copper sleeves.It is widely applied in auto chassis,forging machine,metallurgical and mining machine,civil engineering,power station,strip rolling industries,etc. |

| Technical |

Load capacity£º70N/mm2

Temperature£º-40¡ãC~+130¡ãC

Speed limit£º2.5m/s

Friction coef(u)£º0.05~0.25

PV LIMIT(DRY)£º2.8N/mm2 .m/s

PV LIMIT(OIL)£º22N/mm2 .m/s |

| Application |

1.Good load capacity and anti-wear.

2.It is used in high load capacities and low speed with rotational,oscillating or frequent stop-start motion.

3.It can work long time without oil in the condition of boundary lubrication,under oil or grease lubrication interval, the work is longer.

4.It is machinable for the thicker of POM.

5.The bushes can be applied in auto chassis,forging machine, metallurgical, civil engineering, power station, strip rolling industries etc. |

SF-2X ¡¡CHEMICAL CHARACTERISTICS |

| Type |

In Air |

In Vacuum |

In water |

In Vapor |

Weak Acid |

middle Acid |

Strong Acid |

In Alkali |

| SF-2X |

OK |

OK |

OK |

OK |

BAD |

NO |

NO |

OK |

|

MMD-10¡¡Friction&Wear Test |

|

| Type |

Time |

Test Condition |

Friction coef(u) |

TEMP.

(¡ãC) |

Wear

(mm) |

| Lubricate |

Speed |

Drang |

| SF-2X |

3hr |

Ö¬ |

0.4m/s |

3.5N/mm2 |

0.071 |

40 |

0.006 |

|

|

|