| SF-1D Hydraulic Bush |

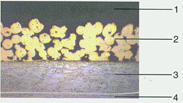

Metallographies Structure |

|

|

1.PTFE with oil fibre 0.01~0.03mm

2.Porous bronze 0.2~0.3mm

3.Steel backing 0.7~2.3mm

4.Tin-plating 0.005mm or copper plating 0.008mm |

| Introduction |

| SF-1D Hydraulic bushing is developed on the basis of SF-1P and meanwhile considering the motion way of oil pump and damper.it is the substitute of and parallels in performance with abroad DP4.In addition to covering the same usage of SF-1P,SF-1D in particular fits frequently reciprocating motion with a high side force.It is a tendency to gradually replace SF-1P with SF-1D,the latter will Cocer a Wide application in auto mobile,motor damper and oilpumps,etc. |

| Technical |

Load capacity£º140N/mm2

Temperature£º-195~+280¡ãC

Speed limit£º3m/s

Friction coef(u)£º0.04~0.20

PV LIMIT£¨Dry£©£º3.8N/mm2 .m/s

PV LIMIT£¨Oil£©£º50N/mm2 .m/s |

| Application |

1.PTFE with oil fibre can protect the shaft,while machine in operation.

2.It is of low friction coefficient,anti-wear.

3.Good running in property.

4.It fits well in motion of circumrotation,sway and to-and-fro.

5.It can be used in food machine,pharmaceutical machine etc.due to lead-free.

6.Besides the same function of SF-1P,SF-1D in particular fits frequently reciprocating motion with a high side force, it is widely used in automobile,motordamper and oil pumps etc. |

SF-1D ¡¡CHEMICAL CHARACTERISTICS |

| Type |

In Air |

In Vacuum |

In water |

In Vapor |

Weak Acid |

middle Acid |

Strong Acid |

In Alkali |

| SF-1D |

OK |

OK |

OK |

OK |

BAD |

NO |

NO |

OK |

|

MMD-10¡¡Friction&Wear Test |

|

| Type |

Time |

Test Condition |

Friction coef(u) |

TEMP.

(¡ãC) |

Wear

(mm) |

| Lubricate |

Speed |

Drang |

| SF-1D |

3hr |

Dry |

0.4m/s |

3.5N/mm2 |

0.175 |

98 |

0.012 |

| SF-1D |

3hr |

Oil |

0.4m/s |

3.5N/mm2 |

0.054 |

46 |

0.004 |

|

|

|